A word about cutting 1/4″ x 1/4″ basswood – using a mitre saw or a NWSL Chopper.

I had to modify the NWSL Chopper to accommodate larger stock see below:

After cutting pieces they are then cut and sanded further to fit using a Minicraft Sander and 180 grit 75mm sanding discs. It is important to get all of the cut ends perfectly square and this is the only method that I know of to accomplish that.

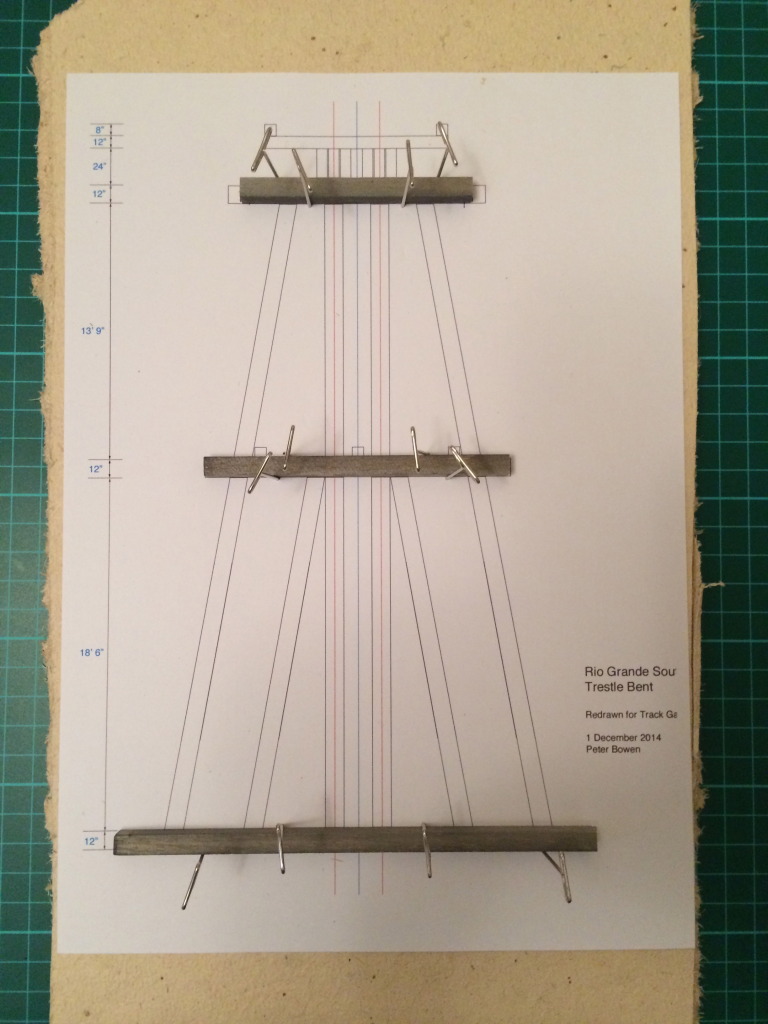

Building the trestle bents on top of a plan. I started using a copy of a plan and soon realised that it was not square and was slightly distorted.

I drew up a new plan to the exact scale and I have included it elsewhere in these postings.

Laying out the components using ‘T” pins.

When I started thinking about this project I knew that it would take a lot of time as each component has to be cut and sanded to fit and it is almost impossible to mass produce items – well it is impossible because I tried grouping a number of pieces together and sanding them all at once – a disaster for one reason or another the only way is to make each one separately and be patient about the outcome and thus a very time consuming job.

Each joint must be a perfect fit or it just will not glue together plus it will look wrong!

Completed two storey trestle bent complete with cross bracing and sway braces.